1N4148 is the most commonly used diode in mechanical keyboards, there are SMD type and THT type, here we use the SMD type, the direction corresponds to the following picture:

SMD diodes are quite tiny and require a little twisting of the light with tweezers to bring out their direction, so our first step is to mount the diodes in a total of 25 places on the top of the keyboard:

After mounting the diode, solder the hot-swap sockets:

Blank supports both Choc and GLP hot-swap socket, you can choose one to install, the pin layout is as shown below:

Connect the jumper P1 under the TRRS after installation:

P1is the default power connection protocol for TRRS, which is basically used by ATMega32U4 ProMicro and RP2040 ProMicro.

If the RP2040 ProMicro shows

Communication Problemson the left and right side, please remove the solder onP1and change toP2and do the communication test again.

Then install the MCU according to the place on the board and the VCC and GND on the top, with the chip side facing down.

The pins are available in either THT or plug-in versions. For testing reasons, the photo shows the plug-in version, so please refer to it.

The plug-in pin header installation.

Next install the TRRS jack and the 2pin tactile switch (you don't need to install the TRRS jack if you only need to install a single-side keyboard).

-

Please be sure to read through the gudie of beekeeb and Keycapsss, the information in both guides will be combined in below:

In order to design this keyboard I ordered the trackpad module kit from the web store, and then bought an FFC connector to build the keyboard on.

- The structure of the keyboard takes reference from beekeeb and bastardkb Dilemma design, the FFC connector will be installed on the back side of the board, on the same side as the hot-swap sockets (please see the photo below for comparison).

- Use the two guides to install the module kit, the length of the spacers posts will need to be adjusted.

- Blank uses

I2Cmode to drive the trackpad.

The photo is from beekeeb:

After finishing the Blank:

Below is a combined information of two trackpad module kit guides from beekeeb and Keypasss:

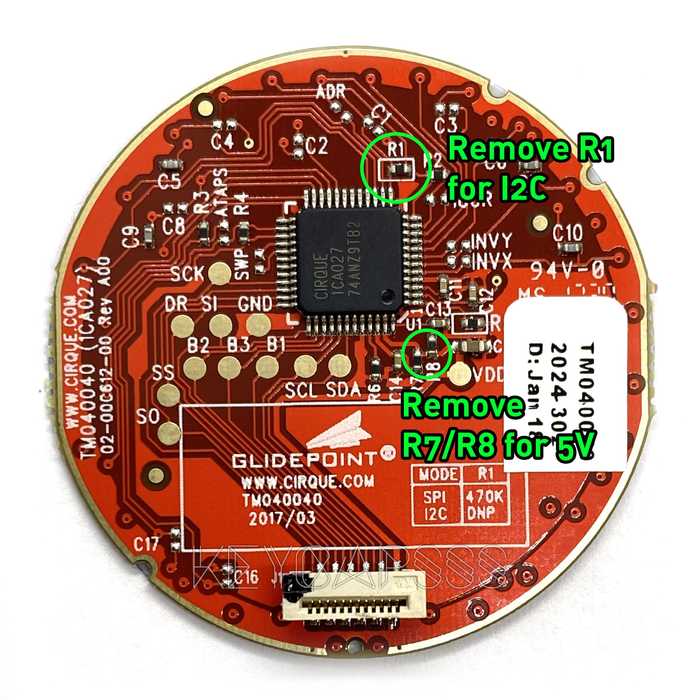

- The

I2Cmode requires to remove some components on the trackpad PCB and add ones that need to be installed:

| MCU | IC | VCC | Resistor R1 | Resistor R7 | Resistor R8 | 4.7K pull-up resistor |

|---|---|---|---|---|---|---|

| ProMicro | ATMega32U4 | 5V | Remove | Remove | Remove | Needed |

| ProMicro | RP2040 | 3V3 | Remove | - | - | Needed |

The trackpad photo is from Keycapsss:

It is difficult to solder the FFC connector with a soldering iron, so it is recommended to use a hot plate or a heat gun to solder it to the PCB.

It is important to note that a certain amount of

fluxwill need to be brushed onto the hot plate.

After the FFC connector is mounted, attach the cable to it.

After attaching the cable, go the cable through the holes on the underside to the other side.

The pull-up resistor part is very simple, bend the pins slightly, insert them into the pad holes on R1 and R2, solder them, and remove the unnecessary parts.

-

Attention when installing the adapter:

- Before installation, all I2C

jumpers on the front side of the PCB must be connected for normal use (check the picture below). - The FFC connector adapter is a module developed by the store to allow users to install it freely, and the installation method should be referred to the guides of the store.

- The use of the adapter will increase the thickness of the mounting position, so you need to adjust the height of the `spacer' by yourself.

- Before installation, all I2C

After removing the resistors from the trackpad, assemble the trackpad body and the 3 covers together. First of all, the diameter of the holes in the cover A and C are not the same, and the order of the cover up and down is different depending on the components installed.

Then place cover A and B in pairs and lay them flat.

The trackpad is placed in the middle, and don't worry about installation errors.

Then stack the cover C plates on top of each other.

Finally screw together with 6mm screws and nuts.

Installation of the rotary encoder part is quite simple, just follow the correct pin layout and solder it.

The bottom plate will be fitted with screws of the correct length for the places shown in the photo, and the installation process will be explained later.

Firstly, the 8mm screws will be screwed in place with nuts.

The 4mm screw part will be held in place with the 5mm spacers.

After putting the washers on the screws, set them aside for now until you can use them.

No matter whether the optional part is a trackpad or a rotray encoder, the final installation is basically the same.

The first part is to build up the trackpad, place the PCB against the bottom plate and install the correct length of spacers as shown in the photo.

Then connect the FFC cable to the connector on the trackpad, follow the direction of the cable and put the plate into the screw holes, and screw it up with 6mm screws.

Lastly, screw the plate and the MCU cover with 3mm screws in order.

The same is done for the rotray encoder part, place the PCB on the bottom plate and install the spacers with the correct length.

Then install the cap.

The covers at the encoder will be stacked in the reverse direction of the trackpad, so you can install the rotray encoder directly after screwing.

Finally, turn the keyboard over to the back and put on the cushion rubber and you're done.

Keyswitches and keycaps can be installed at the end, depending on your choice. Here, we used Kailh Choc v2 Black Cloud.

The keycaps used are Tai-hao THT low profile, blank version.

DONE!

The firmware installation process can be different. If you want to flash before building the keyboard, please use the correct method for the MCU you want to use.

-

Before building:

- ATMega32U4 ProMicro: can use

QMK ToolboxorQMK MSYSto flash the firmware. - RP2040 ProMicro: drive

RP_BOOTmode, then put the.uf2firmware to the hard-disk。

- ATMega32U4 ProMicro: can use

It have 2 methods to drive the

RP_BOOTmode:

- Press the

BOOTbutton on the MCU then plug in to your device.- After plugging into the device, press the

BOOTbotton about 1 second, then press the bottonRESET.

-

After building:

- ATMega32U4 ProMicro: can use

QMK ToolboxorQMK MSYSto flash the firmware, one press theRESETbotton to drive the flash mode。 - RP2040 ProMicro: press twice the

tactile switch(RESET) on the PCB side and hold 1 second, then it will drive theRP_BOOTmode, put the.uf2firmware to the hard-disk to flash.

- ATMega32U4 ProMicro: can use

There are also having

RESETandBOOTholes on the back of the MCU that can be triggered by tweezers, so you don't have to worry about flashing issue.

RP2040 ProMicro

Communication problem, please remove theP1jumper on the board and change it toP2connection and test again.

For the keyboard keyswitches section, turn on

VIALand go toMatrix Tester, if you have to tap keyswitches go through all of them, if not use tweezers to test forsolder padsorpinson each key.

To test the keys on the top of the rotary encoder, open the switch against the

Layoutsection and test with theMatrix Tester.